Hole Threading Tool

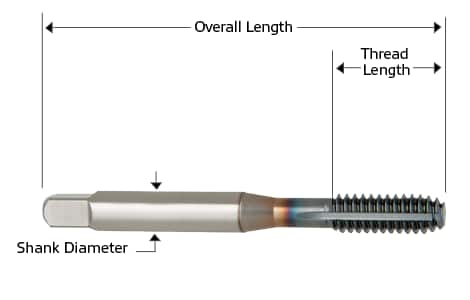

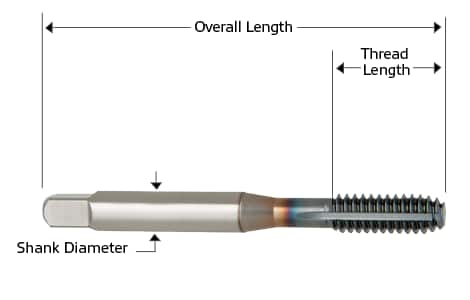

All threading or cutting tools. The pitch is calculated by measuring the distance between the first and second tooth.

The Myth Of Deep Hole Threading

Once you finish this process youll be able to torque down the bolts like normal.

Hole threading tool. To make the drilled holes in perfect size on an object the reaming preocess is performed. Cutting taps come in sets of 3. High Strength Ferritic Martensitic and PH Stainless Steels 350-450 HB.

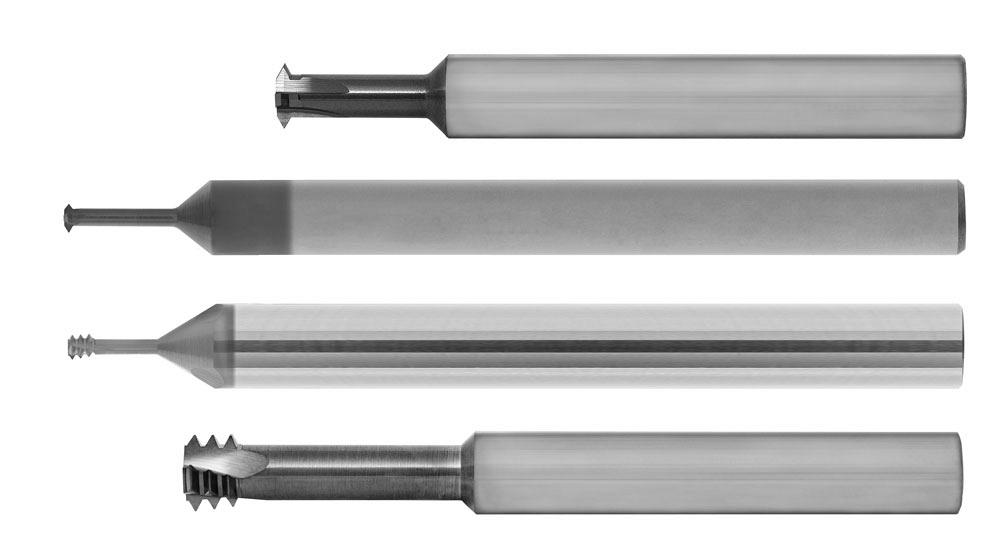

195 rows The core hole is pre-drilled with a core hole twist drill. Internal threading tools add threads to the inside diameter of drilled or cast holes in workpieces. Thread mills can produce a full thread close to the bottom of a blind-hole.

The tap set had a handy little tool for measuring this but it is also easily possible to count threads next to a ruler. The set has both metric and SAE threading tools and covers all the common sizes. With the right tools thread milling large bore diameters doesnt have to be daunting.

Whether for tapping for internal threads in through holes and blind holes or for external threads too. Taps for Deep Blind Hole. External threads such as for bolts and studs are made by using a tool called a DIE which is applied to a specific diameter.

Tapping is usually used to make threads in small holes after drilling while thread milling tends to produce threads in larger holes. When the hole is blind a tap can only reach so far because it has a tapered point. This one is yet another large tap and die set with a.

Shop our line of manual and power threaders and accessories. GearWrench 3887 75-Piece Tap and Die Set. Economy Carbon Steel Taps Often used for thread repair and occasional hand tapping these carbon steel taps can thread holes in most metal and plastic but they have a shorter tool life than standard taps.

Click here for the best tap die set. Tapping uses a tool of the same size as the thread forcing the chip through the thread to evacuate while thread milling uses a tool with a smaller size than the thread so thread milling achieves a better thread quality than tapping. When its a large hole meaning 1 to 1½ in diameter and larger or a taper pipe thread milling is preferred.

As an innovative manufacturer of precision tools for machining Walter offers you efficient solutions for all common thread production methods. Manufactured from high speed steel for a clean cut with precision-ground threads for accuracy. And finally the set is made in USA and comes with a quality storage case.

So the machine operator has the ability to adjust thread size using a strategy similar to using an end mill rather than a drill bit to make a hole. The threading tool stays stationary while the lathe rotates the workpiece against the cutting tip. They should be used in that order when tapping holes that.

Cutting taps usually have sharp flutes somewhat like the spirals of a drill where the chips can accumulate and be ejected out of the hole NOTE. When one point of an insert dulls rotate it to use a sharp point. No matter whether the methods are non-cutting such as thread forming or.

This tool allowed the through hole to be drilled and the threads at both ends of the hole to be milled in one operation eliminating the need for a separate threading operation. Long Blade for Improved Access. The cutter first plunges to drill the hole.

Internal Threading lay down. The thread mill first entered the hole and milled the threads at the bottom of the hole the extended length necked shank prevented the tool from interfering with the. A tap can only do what is ground into the tool so the user needs one tool for left-hand threads and another for right-hand threads.

The tool which is used in reaming preocess is called Reamer. Chasing tapped holes cleaning up threads. A starter tap a midway tap and the bottoming tap.

High Strength Austenitic Stainless and Cast Stainless Steels 150. A distinction is made between metric thread types and inch thread types. Always remember when using a hole saw to start slowly and be sure to use a coolant when cutting metals or ceramics.

In a pinch when clean-up is necessary using a tap made for Cast Iron or Brass may be a ready solution as both materials require the geometry recommended for re-threading. The thread gauge for our screw is 16 threads per inch. The cutting tool tip is shaped like a drill or center-cutting endmill while the body has a thread-shaped form with a countersink cutter form near the shank.

Sized to cut oversized threads these tools are often used to tap holes where the threads will shrink due to heat treatment or plating. In the process of tapping internal threads are made with a tool which is called tap. RIDGID pipe threaders bring confidence and precision when joining forming or connecting pipe.

These tools come with one high-speed steel insert for use on steel and stainless steel and one high-speed steel insert for use on softer materials such as aluminum and brass. When a hole requires threads part manufacturers basically can perform conventional tapping cold-form tapping or thread milling. A hole saw can be used with various different materials including mild steel cast iron stainless steel tool steel aluminium brass and wood.

15 M Stainless Steel 15 M1. They have a single cutting tip at the end of a shank and attach to a lathe. This information is helpfully printed on the tap itself.

It removes a small amount of material from the object. Threading taps are a tool used to create screw threads tapping into a pre-drilled hole to create a clean fitting for bolts in metals and plastics. Austenitic Stainless Steel 130-200 HB.

Internal threading is done by using a tool called a TAP in a hole drilled to a specific diameter for the thread size and pitch you want to cut. If special pitch diameters are required a special tap should be ordered for the job. Used in engineering and manufacturing threading taps work like a drill but due to the unique shape of a tap when screwed into a piece of material screw threads.

For cleaning and recutting damaged or badly formed threads in socket boxes. Taps for Short Blind Hole. For metric thread types the dimensions are given in millimetres.

In order to perform the thread insert process you need purpose-built tools to drill the hole bigger tap new threads and install the metal insert. Thrilling is the process of threading and drilling accomplished in the reverse order internal threads using a specialized cutting tool on a CNC mill. In our case we had 38 screws and therefore needed to drill holes of 516.

A tool that makes the helical portion of a threaded hole by cutting material as it moves along a predrilled hole. A threaded hole is milled at a high RPM and the tool helixes into a previously-milled hole. However you might notice that the threads are more solid than stock when the new insert is installed.

-min.jpg)

Taps And Dies Threading And Rethreading Tools

The Myth Of Deep Hole Threading

Cored Holes Direct Tapping With No Tool Breakage Yamawa

The Advantages Of Thread Milling Triumph Tool

Thread Milling Simplified Cutting Tool Engineering

Cored Holes Direct Tapping With No Tool Breakage Yamawa

Gsr Hand Tap Guides Threading Tools Guide Gsr Blog

Carbide Id Acme Threading Tool 29 Degree 4 5 6 8 10 14 16 Tpi

Being Prepared Hole Preparation Prior To Tapping North American Tool A Gws Tool Group Company

Hand Taps And Proper Threading Techniques Westport Corp

Amazon Com Abn Large Tap And Die Set Metric Tap And Die Kit Rethreading Tool Kit Thread Maker Hole Threader 110 Piece Set Metric Industrial Scientific

How To Improve The Quality Of A Threaded Hole Triumph Tool

A Look At The Different Types Of Thread Taps

Thread Forming Taps Technical Information Msc Industrial Supply Co

How To Rethread A Hole Using A Tap And Die Set Youtube

3 Tools For Internal Threading Tapping

How To Choose The Right Type Of Tap

How To Improve The Quality Of A Threaded Hole Triumph Tool

Post a Comment for "Hole Threading Tool"